Basic Terms of fabric preparation equipment

Batch Machines:

In batch processing, machines are used where the entire load of fabric isimmersed in the total amount of liquid needed for that process. These machines are

primarily used to dye fabric, however, in many cases they are also used to prepare

fabric prior to the dyeing cycle. The section that follows describes some of the more

popular machines.

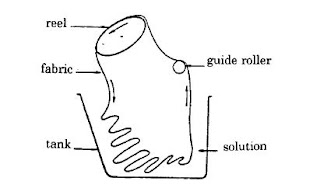

1. Becks

A beck is the simplest type of wet processing batch equipment. It is a large vatwhich holds the entire lot of fabric. The fabric is fed into the machine in the form of

a rope and is made into a continuous loop by sewing the two ends together. The

length of the loop is equal to a piece length, usually 100 to 200 yards. The fabric is

agitated by the action of a lifter wheel which gently moves the fabric through the

liquor by lifting and dropping the rope in and out of the liquor. Lot size is

determined by the number of loop strands that can be accommodated by the machine

and is a function of the front width of the machine. Commercial machine are

available ranging from one strand to 16 strands. A schematic of a beck is shown in

figure.

Schematic of an Atmospheric Beck

2. Jet Machines

Jet machines are similar to becks in that a continuous loop of fabric circulatesthrough the machine. They differ however in that a stream of liquor is forced

through a venturi tube. This provides the force to propel the fabric through the

machine. Temperatures in Jet machines that operate at atmospheric pressure cannot

exceed the boiling point of water; however, higher temperatures can be obtained in

those that are operated under pressure. An advantage of the jet machines is that

lower liquor ratios can be used. In a beck, the liquid is stationary and the fabric

moves through it. In a jet however, both the liquid and the fabric move in relation to

each other. This increases the rate of interchange between the liquid and fabric and

speeds up the process. The distinguishing features of jet machines are the venturi

tubes which create the force to circulate fabric, and circulating pumps which cycle

the bath through the venturi tubes. Figures shows schematic diagrams of pressure

and atmospheric jets.

Atmospheric Jet

Schematics of Jet Machines

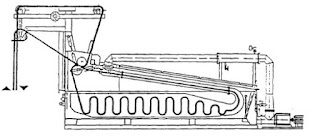

3. Jig

A Jig or Jigger is a batch machine which handles fabric in open width. It isa simple machine consisting of let-off and take-up rolls, a trough containing the

processing liquor and guide rolls which allow the fabric to pass from the let-off to the

take-up roll. After all the fabric transfers, the driving mechanism is reversed and the

fabric makes a second pass through the liquor by returning to the original let-off roll.

The cycle can be repeated as many times as it takes to achieve the desired effect.

Figure shows a schematic of a jig.

Schematic of a Jig

0 Comments