Machine MainParts:

1.Creel Section :

Bobbin Stand/ PackageStand Holder

Plastic Disk

Post

Post Controller

Sensior

Ciramix Guide

2.Reed :

Control Box

3. Pulley Stand

4.Head Stock :

Motor

Counter Roller

Traverse

Hook

Pressure Roller

Briefly Description of DifferentParts:

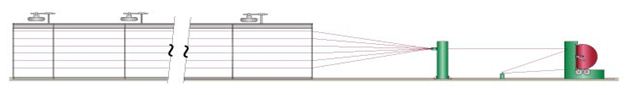

Creel

In ball warping, all the packages are loaded into the adapters of the creel of ball warping machine. The creel is normally designed to accommodate about 330 to 430 packages. The creel may be of different types, such as Magazine Creels and Traveling Package Creels. The passage of yarn in ball warping are shown in Fig. 1

Fig.1 : Passage of yarn in ball warping

Fig. 2: Ball Warping Machine

The Magazine creels are straight-line creels having a reserve yarn package placed beside the running packages (Fig. 3). The tail end of the running package is knotted with the start end of the reserve package. When the running package is depleted, the warper continues to run with the from the reserve package.

Fig. 3: Magazine Creels

The traveling package creels are V-shaped creels. The running yarn packages are kept on the outside of the V and the full yarn packages are loaded on the inside of the V. When the running packages are emptied, the yarn spindles on the creel are rotated so that the full packages move to the outside of the creel and the empty packages move towards the inside of the V-creel for replenishment. The warping machine is start with the new yarn ends. The empty packages are unloaded and replaced with new full packages.

Fig :Ball WarpingLogs

Tensioners

The individual yarn from each package loaded in the warping creel are passes through a tensioner.There are different types of tensioners available for ball warping machines. The different types of tensioners are as below:

Fig.:Typical Yarn delivery to the warp preparation machines

0 Comments