Stitch Classifications:

The stitches are divided into six major stitch classes based on the mechanism used to control the lower thread:

1. Class 100—Chainstitch

2. Class 200—Hand stitch

3. Class 300—Lockstitch

4. Class 400—Multi-thread chainstitch

5. Class 500—Over edge stitch

6. Class 600—Cover stitch

Class 100—Chainstitch

One of the simplest stitch types, the chainstitch has one or more needle threads and is formed by intralooping. This stitch is very insecure and unravels easily if a stitch is broken or skipped or if the last loop is not fastened securely. This stitch is used for sewing buttons and buttonholes, hemming, basting, and padstitching.

Class 200—Hand Stitch

Generally formed by hand, the hand stitch is made with a needle that is passed from one side of the material to the other as a single line of thread. The most important machine to duplicate this stitch is a pickstitching machine (209); pickstitching is used as a decorative detail on the outer edges of jackets.

Class 300—Lockstitch

The most common stitch type, the lockstitch has two or more groups of threads that interlace to form the stitch. One group is called the needle threads and the other the bobbin threads. These stitches do not unravel easily and always require a bobbin. Very versatile, they are used for seaming, hemming, and setting zippers and pockets.

Class 400—Multi-Thread Chainstitch

Sometimes called a double-locked stitch, the multi-thread chainstitch has two or more groups of threads that interlace and interloop with each other. One group is called the needle threads and the other the looper threads. This stitch is actually stronger than the lockstitch; however, if the threads are not properly secured on the finishing end, it will unravel. It is used for seaming and in combination with the overedge stitch on overlock machines. When used for seaming, the needle thread determines the seam strength and the looper threads can be finer.

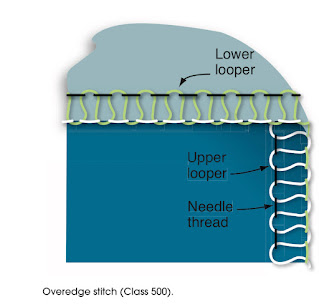

Class 500—Overedge Stitch

The overedge stitch is formed with one or more groups of threads that interloop to form a thread sheath around the fabric edge. The most common stitches have one or two needle threads and one or two looper threads.

Overedge stitches are very elastic and do not unravel easily. They are used for neatening edges, seaming woven and low-stretch knitted fabrics, and forming decorative edgings. All of the stitches can be used for neatening; however, one- and two-thread overedge stitches cannot be used for seaming because the stitch opens up when stressed transversely. And because the stitches produce a closed seam that cannot be pressed open, it is not always acceptable on better garments. When used for seaming, the needle thread determines the seam strength.

This stitch is frequently combined with a multi-thread chainstitch (401) to seam and finish the edges.

In this text, the terms overedge machine, overlock machine, and serger are used interchangeably because you may encounter any of them in the workplace.

Class 600—Coverstitch

The most complex stitch class, the coverstitch is generally formed with three or more groups of threads that cover the raw edges of both surfaces. Very elastic, it is used to create low-bulk and decorative seams on underwear and knitted casual garments. Threads should be strong with a soft hand.

0 Comments