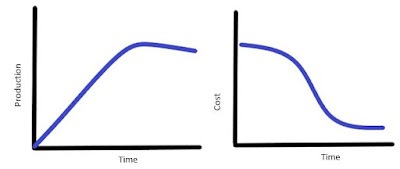

Labor productivity:

The resource inputs are aggregated in terms of labor hours. Hence this index is relatively free of changes caused by wage rates and labor mix. By improving methods of work (eliminating unnecessary movement, etc.) the output of a worker can be increased.

(a) In terms of hours:

Productivity = Production in standard hours / Actual man hours

(b) In terms of money:

Productivity = Total cost (or sale value) of output / Number of workers

The productivity of labor can be increased by increasing efficiency of labor, reducing idle time.

For example,

let us take a turner who was producing 20 pieces an hour and the same turner, by the improved methods of doing work is able to produce 25 pieces an hour. Then productivity has increased by [(25 − 20)/20] × 100 = 25%.

Machine productivity:

By use of sophisticated modern machines, better method of manufacture and reducing idle time of machines, the number of pieces (items) produced by a machine per hour can be increased.

Productivity = Output in standard hours / Actual machine hours

For example,

let us assume a machine was producing only 100 pieces per working day of 8 hours. The machine tool has fitted with a better tool that permitted more depth of cut and higher cutting speed. As a result the output from the machine increased to 130 pieces in a day of 8 hours. In this case, the productivity has increased by [(130 − 100)/100] × 100 = 30%.

Machines and equipments necessary for the operational activities of the enterprise, including those intended for transport and handling, heating or air conditioning, office equipment, computer and the like.

![Labor and Machine Productivity in Manufacturing Labor productivity: The resource inputs are aggregated in terms of labor hours. Hence this index is relatively free of changes caused by wage rates and labor mix. By improving methods of work (eliminating unnecessary movement, etc.) the output of a worker can be increased. (a) In terms of hours: Productivity = Production in standard hours / Actual man hours (b) In terms of money: Productivity = Total cost (or sale value) of output / Number of workers The productivity of labor can be increased by increasing efficiency of labor, reducing idle time. For example, let us take a turner who was producing 20 pieces an hour and the same turner, by the improved methods of doing work is able to produce 25 pieces an hour. Then productivity has increased by [(25 − 20)/20] × 100 = 25%. Machine productivity: By use of sophisticated modern machines, better method of manufacture and reducing idle time of machines, the number of pieces (items) produced by a machine per hour can be increased. Productivity = Output in standard hours / Actual machine hours For example, let us assume a machine was producing only 100 pieces per working day of 8 hours. The machine tool has fitted with a better tool that permitted more depth of cut and higher cutting speed. As a result the output from the machine increased to 130 pieces in a day of 8 hours. In this case, the productivity has increased by [(130 − 100)/100] × 100 = 30%. Machines and equipments necessary for the operational activities of the enterprise, including those intended for transport and handling, heating or air conditioning, office equipment, computer and the like.](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEhM0WY1O0yNJANFhcZ9ee1lbG9LbsDQJN44z8J0QzUUaszxg7F7iutRtjSL2_kQqIZnw1tpxRfai7avg2X585o457sJ_AUJAB8bFUMJHGIABBLDtPXRWn1J-MhwrH11xD4-mf1VzyXrRJJ4ufPHVH8MJlvndAIDIwmdYiU7cQoAjTz87Ntn4-6Va26DvA/w200-h56/labour%20productivity.JPG)

0 Comments